As the world moves towards a more sustainable future, electric cars have become a significant part of the automotive industry. These eco-friendly vehicles rely on efficient and powerful batteries to provide the necessary energy for a smooth and reliable ride. In this article, we will explore the process of “How To Make A Battery For An Electric Car” to shed light on the fascinating technology behind these vehicles.

Understanding Electric Car Batteries

Electric car batteries are the heart and soul of these modern vehicles. They store and provide the electricity needed to power the electric motor, which drives the car. These batteries are designed to be high-capacity, durable, and rechargeable. To make a battery for an electric car, you need to follow a precise process that involves several key components.

Materials You’ll Need

To embark on this journey, you’ll require the following materials:

- Lithium-Ion Cells: Lithium-ion cells are the most commonly used battery cells in electric cars. They offer a high energy density, making them efficient for powering vehicles.

- Battery Management System (BMS): The BMS ensures the safe and optimal operation of the battery. It monitors cell voltage, temperature, and overall health, preventing overcharging and overheating.

- Electrolyte Solution: The electrolyte is a crucial component that allows ions to move between the positive and negative electrodes, generating electrical energy.

- Anode and Cathode Materials: These materials are essential for storing and releasing electrical energy. Common materials include graphite for the anode and lithium cobalt oxide for the cathode.

- Separator Material: Separators keep the anode and cathode from coming into direct contact, preventing short circuits.

The Manufacturing Process

Now, let’s delve into the detailed steps of how to make a battery for an electric car.

- Electrode Preparation

- Create the anode and cathode by applying the electrode materials onto a conductive current collector.

- Ensure uniformity and precision in the electrode coating to optimize battery performance.

- Assembling the Cell

- Stack the anode, separator, and cathode together to form a cell.

- Introduce the electrolyte solution into the cell to facilitate ion movement.

- Sealing the Cell

- Seal the cell tightly to prevent any leakage of electrolyte and to maintain a safe operating environment.

- Battery Module Assembly

- Connect multiple cells in parallel and series to form battery modules with the desired voltage and capacity.

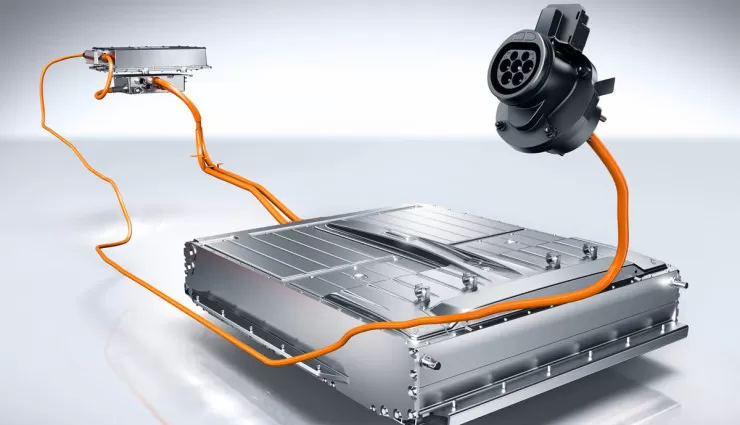

- Battery Pack Assembly

- Combine multiple battery modules to create the final battery pack that will power the electric car.

- Integration with the Vehicle

- Install the battery pack into the electric car, ensuring it is properly connected to the electric motor and the BMS.

Ensuring Quality and Safety

The “How To Make A Battery For An Electric Car” process is not just about assembling components. Quality control and safety measures are paramount. Battery manufacturers perform rigorous testing to ensure their products meet the highest standards. This includes testing the battery’s performance, safety features, and longevity.

Environmental Considerations

The production of electric car batteries has raised concerns about its environmental impact. Disposal and recycling of batteries are important aspects of sustainability. Manufacturers are continuously working on improving battery recycling processes to reduce waste and minimize their carbon footprint.

Conclusion

In the world of electric vehicles, the battery is the cornerstone of sustainable transportation. Learning “How To Make A Battery For An Electric Car” is a complex but fascinating process that combines cutting-edge technology and environmental consciousness. As electric cars continue to grow in popularity, advancements in battery technology will play a pivotal role in shaping our eco-friendly future on the road.